12 Acres Brewing recently commissioned their brand-new craft brewery cooling system in Killeshin Co. Laois. Kilkenny Cooling Systems designed and manufactured several pieces of the equipment which forms part of this brewery, and in this case study, we will look at this project in further detail.

The Brand

12 Acres is already a very well established name in the Irish craft brewing scene, producing a delicious well balanced pale ale from their very own spring water and barley. Indeed, the motto of the brewery ‘From our Ground to Your Glass’ reflects their ethos of controlling every stage of the brewing process right through to the final pour. It is this approach that 12 Acres maintains is what makes their beer so special. Indeed, the ethos must be working for them, as they beat very significant competition from all over Ireland to be shortlisted for Blas Na hEireann Irish Food Awards just a few days ago!

The brewery, which is located just a few kilometers from Carlow town, was recently kitted out with a selection of Kilkenny Cooling Systems built brewing and cooling equipment.

The Brewery

When it comes to supplying craft breweries and distilleries with equipment, Kilkenny Cooling Systems has a lot of experience. We have supplied Kinnegar, Cleverman, Yellow Belly, Boyne Brewhouse, and several other breweries and distilleries with high quality tailor-made cooling equipment. However for the 12 Acres project, we had a more input.

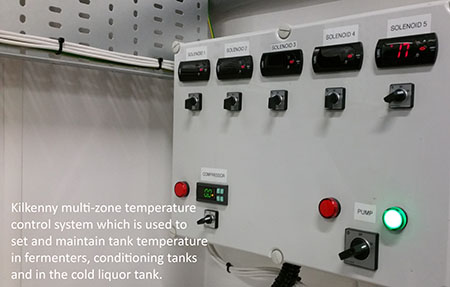

Co-founder Paddy McDonald visited the Kilkenny Cooling Systems factory with a set of plans for various storage vessels and processing equipment. As with many other craft breweries, a multi zone process cooling system with digital temperature controllers was top of the list, and this was duly specified and supplied. In addition to this, the brewery was provided with remanufactured hot and cold liquor tanks for storing the brewing liquor.

Kilkenny Cooling Systems also designed and built a custom made frame to fix the tanks into position, allowing them to be stacked in the brewery – saving space.

Of particular interest on this project was the large whirlpool tank which was manufactured here at Kilkenny by modifying an existing stainless steel vertical cylindrical milk storage vessel and fitting it with an angled inlet. Wort is pumped at high velocity though this inlet into the tank to create a whirlpool effect, efficiently separating the hops and trub from wort after the boil.

Outcome

The result of the extra time and effort spent at the design stage has paid off, because 12 Acres are now proud owners of an extremely robust brewery, which was designed and built specifically to meet with their own exacting requirements. Here at Kilkenny Cooling Systems we are delighted that we had such extensive involvement in this project and wish the 12 Acres team the very best in all future brewing endeavours.

“I was very happy with the equipment and the service provided by Kilkenny Cooling Systems and would be happy to recommend them to any brewery buying new equipment ”

- Paddy McDonald, 12 Acres Brewing